What is Endurabolt

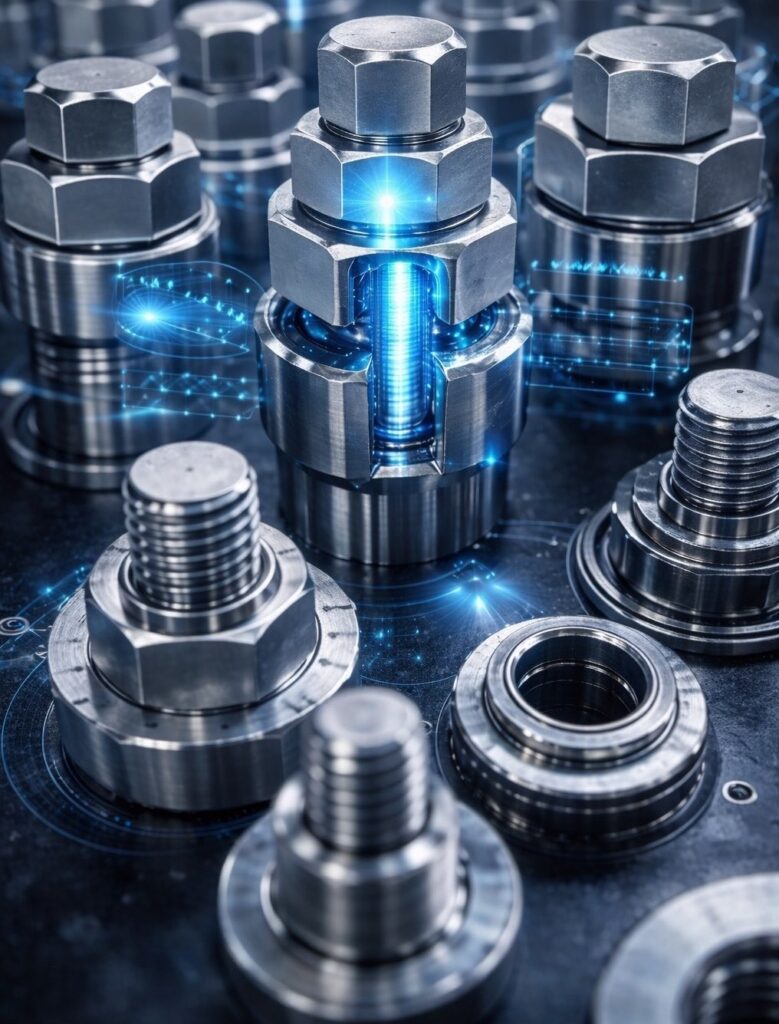

Endurobolt is a next-generation structural fastener developed to address long-standing limitations in how bolted joints are designed, installed, and monitored.

Unlike conventional fasteners, Endurobolt incorporates embedded sensing at the point of elongation. This enables direct measurement of preload, load variation, and joint behaviour throughout the asset lifecycle — not inferred estimates or periodic inspection snapshots.

The result is improved confidence in joint integrity, reduced uncertainty in safety-critical applications, and a clearer understanding of how joints perform in real operating conditions.

Key Benefits

Reduced cracking and fatigue risk

The patented fastener architecture significantly reduces the risk of cracking and fatigue compared to conventional designs.

Direct, in-situ load measurement

Embedded sensors measure joint load precisely at the point of elongation, improving accuracy and confidence.

Remote monitoring and reduced inspection

Continuous remote monitoring reduces inspection burden and increases confidence in assets while in service.

The Challenges of Safety Critical Bolted Joints

Designed For Demanding Environments

Endurobolt is suited to safety-critical applications where joint integrity, reliability, and access constraints are key considerations.

Wind & Renewable Energy

Critical joints exposed to cyclic loading, vibration, and harsh environmental conditions. Designed to support long service intervals and reduce inspection burden

Civil & Transport

Structural joints in bridges and transport assets where inspection access is limited and long-term integrity is critical.

Rail & Marine

High-vibration, fatigue-prone environments with constrained access. Supporting repeatable performance & lifecycle reliability.

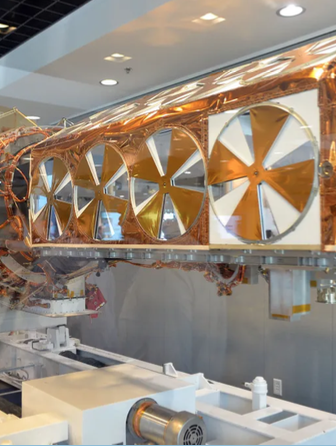

Aerospace & Space Systems

Precision fastening where weight, traceability, and controlled preload are essential in demanding operational conditions.

Energy & Industrial

Structural joints in bridges and transport assets where inspection access is limited and long-term integrity is critical.

Designed for real-world use

Endurobolt shifts bolted joints from assumption-based management to evidence-based insight.

By measuring load directly within the fastener, engineers gain visibility into how joints behave during installation and throughout service. This allows informed decisions around maintenance intervals, asset life, and risk management.

Rather than relying on periodic inspection or conservative safety margins alone, Endurobolt enables a clearer understanding of real-world performance.

Endurobolt is designed to integrate into existing fastener standards and installation practices.

It avoids specialist tooling or process change, allowing adoption without disruption to established engineering workflows.

Load is measured directly within the fastener at the point of elongation.

This enables validation of preload and joint behaviour based on measured data rather than inferred torque values.

Endurobolt is developed within controlled engineering and quality frameworks.

Traceability, documentation, and verification support use in regulated and safety-critical environments.

Discuss Your Application

Briefly outline the application, environment, loading or any specific requirements.